DOCUMENTATION

ATELIER SCHMID – ARTISANAL WATCH AND CLOCKMAKERS – REVISION, RESTORATION AND SALE OF OLD AND ANTIQUE CLOCKS

A CLOSER LOOK AT MY WORK

Click through some impressions of my daily work in the workshop.

Restoration of a French mantel clock

The clock described in the following is a French mantel clock in a robust bronze case from the second half of the 19th century, circa 1860. Antique clocks of this type were produced in all manner of variations at the time. The Napoleon III era, in particular, assimilated all prior styles of clockmaking. Countless models of mantel and table clocks, some splendid, some kitschy, were presented for sale to the expectant aficionados of the Zeitgeist. Materials such as marble, alabaster, pewter and burnished bronze captured the spirit of that age in the history of clocks. Even today, a wide variety of models can be acquired at auctions or, with a bit of patience, stumbled across and bought at antique markets. It’s a favourable time for it, as prices are low owing to minimal demand.

Restoration work

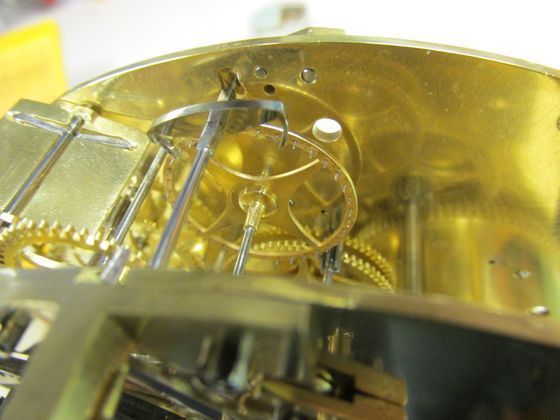

The surface of the solid clock case, as well as all the appliqués, were originally fire-gilt. Over the years, however, this finish was almost entirely damaged as a result of improper care and substandard repair work. The large Paris movement is of good quality and features a rack striking train. The movement is regulated by a Brocot regulator system, which was widely used in movements of this type after 1850. It enabled very precise regulation of the clock’s accuracy.

With the complete dismantlement of the movement mechanism and individual components, various signs of wear become evident. In this case, among other things, the two mainsprings of the going and striking trains broken owing to corrosion.

Mainsprings of the appropriate dimensions and tolerances must now be ordered for both barrels. The critical factors in the selection are: the height, the spring force and the inner diameter of the barrel.

The springs are tensioned using a special spring winder and installed in the mainspring barrel drums. The spring steel is lubricated with a special synthetic grease. In this case, and in view of the spring thickness of 0.38 mm, I use Motorex lghx 176.The spring must not be excessively greased as the grease will otherwise get into the bearings of the spring core. The spring core bearings are lubricated with Moebius 8200. The ultrasonically cleaned and assembled barrels are ready for installation. Now, all wheel pivots must be meticulously sanded and polished. Only then will a decision be made on which wheel bearings need to be refitted.The new bearing positions must be centrically drilled and reamed out to 3/100 mm. Now the appropriate hard brass bearings can be pressed in. The lateral play of each pivot must be checked before the oil sink is slightly re-milled.All components and parts made of brass can meanwhile be cleaned in the ultrasonic bath at 55–60°C. (Cleaning solution: Ortimex) Minor corrosion discolouration and rust are painstakingly removed, as much as possible, with a fine wire brush from the steel surfaces of pinions, levers and arbours. If necessary, the steel pinions are re-worked with polishing paste.

The acid damage from previous, improper work on the movement mechanism is still clearly evident on the plates.In this case, a slightly abrasive surface treatment is absolutely essential in order to restore the material to its original colour.

After the subsequent final cleaning, the materials are restored to their former lustre. It ought to be emphasised that restorative treatments of this type should only be carried out in extreme cases.

It is absolutely fine for the movement plates to retain the dents and scratches they have acquired over the years. They are part of the object and its history.

Now for the problem of the cannon pinion: to position the trigger of the minute hand at exactly 12 or 6 o’clock, they had simply pushed the cannon pinion into the desired position and thus twisted the friction section and rendered it inoperable. Upon attempting to restore the original state, the material broke, as was almost to be expected.

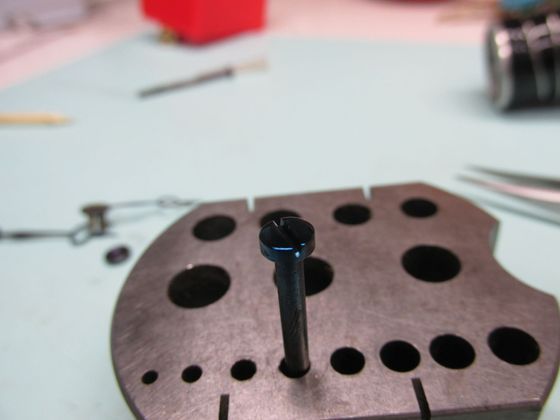

The positions to be joined with hard solder are first lightly sanded and thoroughly cleaned. Then the break position is treated with soldering fluid and then precisely joined with hard solder.All steel screws are blued over the spirit lamp at just under 300°C.

To prevent premature dirtying of the clock oil, all pivot bearings must be thoroughly cleaned out with pointed beechwood.

The escapement wheel teeth and steel anchor pallets are subjected to a special stop-oil procedure so that the escapement grease stays in the same position over a period of years.After the main cleaning job is performed on all parts, the movement is assembled and all functions in the striking train set to the correct positions. The upper and lower plates are placed on top of each other and pinned together.On the dial side of the movement, the depthing of the cannon pinion and minute wheel must be taken into account.Now the movement is provisionally set in motion with the pendulum and regulation system installed in order to check the escapement function and make adjustments if necessary.

The movement has now been completely revised and is ready for reinstallation.

Now we turn to the preparation and restoration of the bronze case.The material has taken on a pronounced patina in some places over the years. The ornamental appliqués are very dirty, which rules out a simple cleaning process with a brush. The case must be partially dismantled. The case is broken down into its individual parts by removing the screws.

The parts are now pre-cleaned one by one and dipped into the cleaning solution in the ultrasonic bath, but only briefly so that the surface doesn’t lose its patina.

After:

After an immediate rinse with water, the components are thoroughly dried with compressed air and a hot air stream to prevent stains from forming.

The revised movement is now installed and precisely positioned.

The adjustment of the escapement drop (regular ticking) as well as the position of the suspension rod within the pallet fork must be precisely checked. After that, the clock must be subjected to a running and function test over at least a four-week period. A French pendulum of this type, with a Brocot pendulum suspension, should not deviate more than a minute over a week’s time.

Voilà!

Restoration of a ‘Breguet à Paris’ table clock (with Neuenburger 3/4-hour striking train)

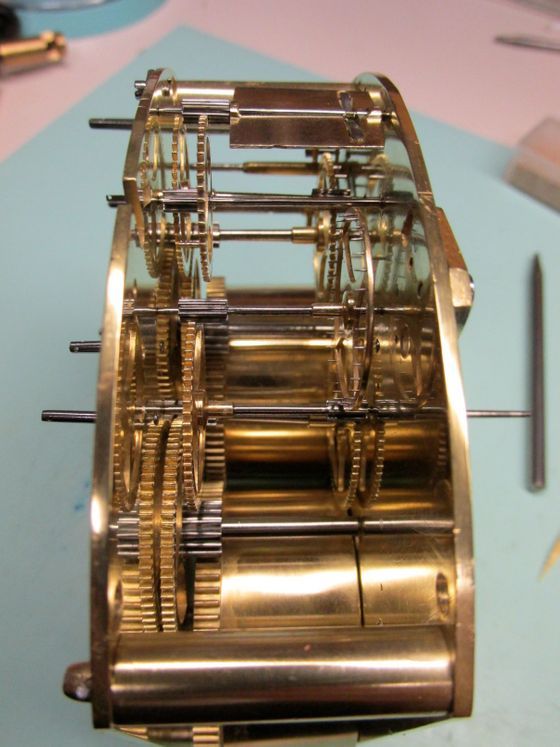

After an initial diagnosis, the restoration of this beautiful table clock revealed itself to be a truly challenging job. The movement with Neuenburger 3/4-hour striking train on two lovely, spiral-shaped gong rods, is of fundamentally good quality. To ensure that this clock can continue to run satisfactorily in the future and bring the condition of the movement back up to a respectable level, a series of interventions will be required.

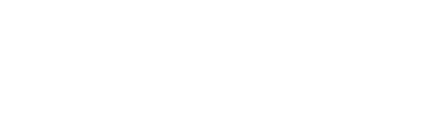

The back plate, which becomes visible upon opening the case, is complete and all of the visible screws are in good condition. They won’t require more than a good polish.

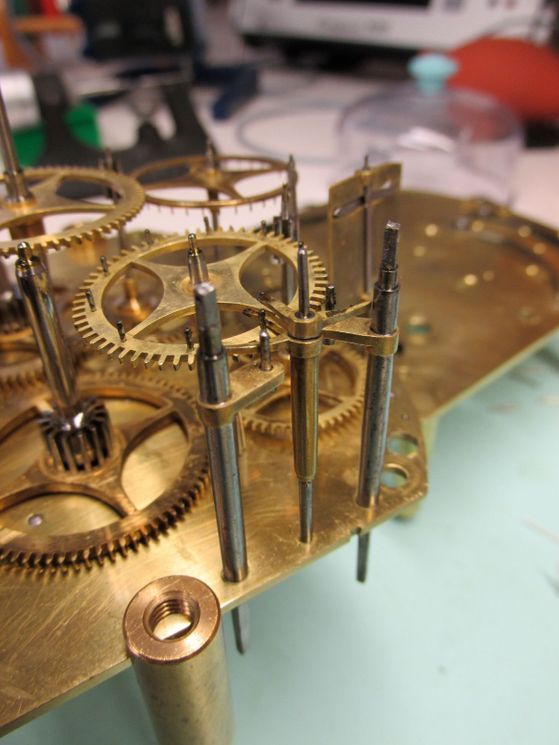

The front plate of the movement was clearly neglected over the years. The screw head for the anchor cock is half broken off. This will require creating a new screw that fits well with the overall appearance using a blank. The rest of the screws have mostly broken off and are all in poor condition. The screw heads must first be brought back into shape using steel punches and other tools. They are then polished with felt and a buffing implement.

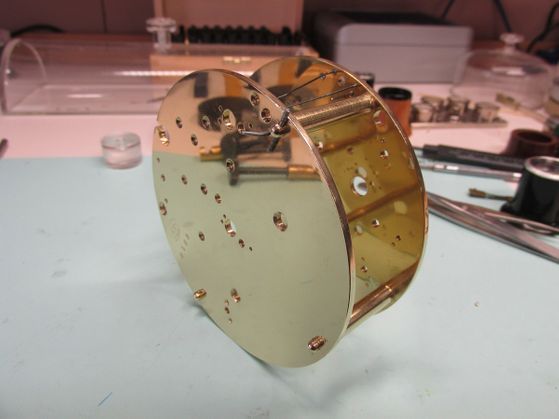

The striking train mechanism features two hammer shafts and a third two-part shaft that connects to the pin wheel. The ends of the hammer shafts each have a short, square piece at the top, on top of which rest the stop elements that fall onto the so-called impact pins and thereby stop the bell hammers in the correct position.

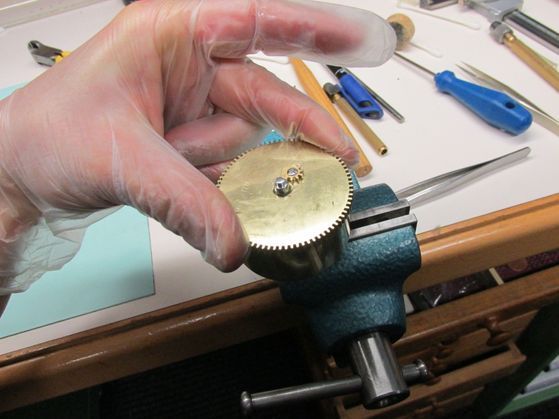

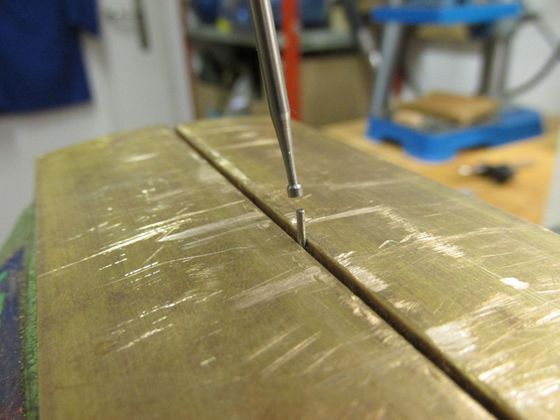

The defective and low-quality stop element is affixed to a piece of old brass with glue. The new functional part will be made out of this brass. After the position drill hole for the square piece, the part is cut from the blank.

Fitting the rough shape of the shaft stop element to the hour hammer shaft requires a great deal of patience. Trying it out time and again on the actual piece is of the utmost importance, because the square piece must ultimately achieve a solid fit. The almost completed part is now given a touch of aesthetic refinement. After cleaning, both stop elements are fixed in place with two matching, conical pins.

Now, various levers, arbours and striking train components must be carefully derusted by hand. This requires a great deal of dexterity. Speed and pressure are critical for a beautiful visual result.

Then we turn to the train as a whole. All wheels and pinions will be checked with regard to function and completeness. Every wheel pivot must be individually examined and assessed. Conical pivots must absolutely be maintained in their original shape. The conical pivot shape was common in that era of clockmaking and had the benefit, in addition to reducing friction, of aiding the retention of oil in the bearings over a longer period of time.

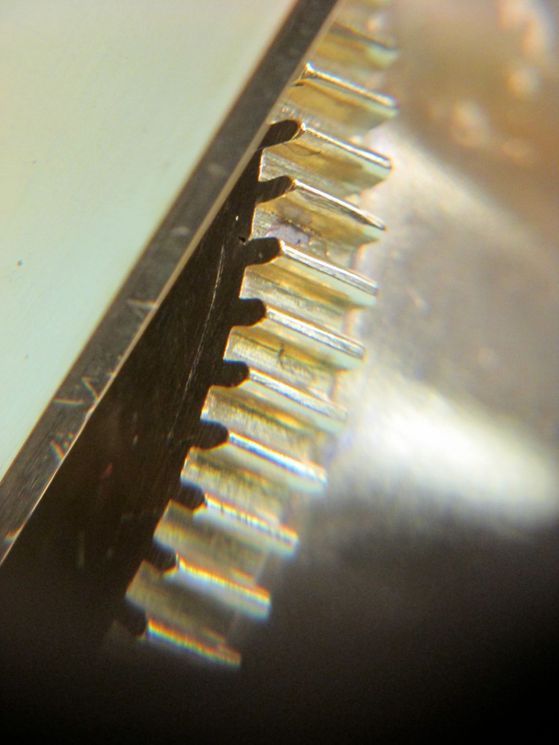

The crown wheel of the mainspring barrel of the going train has been poorly repaired in the past and is too large in diameter for this position. The four defective tooth units result in poor engagement in the eight-day wheel, which can lead to a blockage of the movement mechanism.

Using the finest clockmaker’s files, this problem zone is filed back into shape and brushed.

Now, we turn our attention to the plates. A gentle pre-sanding must be carried out with 1,000-grit sanding paper.

‘Metharex’ metal polish gives the material a lasting shine. It should emphasised here again that minor scratches and dents should still be visible. They are a part of the history of the clock.

Fortunately, the mainsprings of the going and striking trains are still in good condition and are also a perfect fit with the barrel in terms of their dimensions. If at all possible, old mainsprings must always be kept, as they represent a clock’s hidden value.Once the surfaces of the barrels have been treated and the components thoroughly cleaned in the ultrasonic bath, the winding position for the going train can be set. This is positioned at one revolution of winding and fixed. As a result, only the optimal spring force of the mainspring is used. Unfortunately, winding positions of the type described here are still often removed even today, which diminishes the value of a clock of this generation.

Once all the components of the movement have been cleaned, the assembly of the entire mechanism can commence. As the parts have taken on a lovely, bright colour owing to the lye bath, it is now important to carry out all further work wearing silicone gloves, as skin contact can result in unsightly oxidation marks later on.

The visible, conical steel pins for the back plate are precisely filed and finished with the hollow reamer.

Now, with the barrels in a relaxed state, the vertical play and meshing of all wheels must be checked.

In this case, special attention should also be paid to the escape wheel pins. They must all come out of the anchor wheel horizontally.

Before the clock is subjected to an initial test phase, the hands movement and all parts of the front plate are fastened and positioned as necessary.

In the first function check, the repère (beat error) of the anchor escapement and all striking train triggers must be checked and set.

The proper functioning of the deadbeat escapement is of prime importance. It is critical to ensure a nice oscillation of the pendulum and regular operation over the function cycle. The anchor and anchor wheel are treated in a stop-oil procedure (immersion bath) to keep the lubrication in place over a period of years.

Now the movement fastening screw damaged when dismantling the movement will be restored and blued over the spirit lamp.

The initial installation of the movement revealed that tightening the upper fixing screw causes a blockage of the striking train. To solve this problem, a hardened pivot steel wire must be turned to size.

The piece is inserted and positioned between the plates and near the upper pallet bridge.

Now it is no longer possible to shift the plates even when tightening the movement fastening points.

After reinstalling the movement again, it is also important to ensure that the cannon pinion and the hour pinion are centred in the dial hole to ensure that the hands don’t touch in the middle. Now the derusted and cleaned gong springs are fastened in the wooden case. The hammer must be installed with due care to avoid clanking.

Finally, the function of the pendulum and the positions of the gong springs in relation to the motion of the pendulum in the case must be checked. The exterior of the case is carefully and gently polished with a case care product.

Voilà, an extremely beautiful piece!

Production of a Savonette spring

A 0.900 silver pocket watch, ca. 1890, of Swiss origin, needs a new solid spring.

The difficulty of this job lies in the shape of the component to be produced and in accurately estimating the correct amount of spring force. Only the hand, the requisite modicum of professional intuition and clockmakers’ files can help master this task. – And it’s just as well that is so!

From my stocks, I choose a piece of round silver steel with a 5 mm diameter. This way, I am sure that I can maintain the maximum dimensions in the shaft area. Using a bastard file, I roughly work the blank into shape with the intention of bending the eventually curved spring in a cold state.

And so it comes to pass – now the piece sits before me in a recognisable shape. At this point, it is important to work with great patience and constant fine-tuning, comparing, shaping, working the spring in such a manner that at least the shaft fits snugly in the case centrepiece.

Only then can I mark the drill position and carry out the step. At this point, the round lip need not have reached its final shape. This will only take place after completion of the thermal treatment.

To give the silver steel the requisite spring action, the material is heated to a cherry-red glow and quenched in oil. Now the steel is hard as glass and also quite brittle.

To minimise the likelihood of black discolouration of the workpiece during this process, I completely cover the material with soft curd soap or rotate it in boron salt.

The workpiece is now sanded smooth down to the shaft so that the bluing effect of being heated over the spirit lamp will be visible.

Once the spring has taken on the colour, it must be immediately removed from the heat in order to ensure the spring steel retains its current shape.

Now the spring is finely polished, finished, and the position of the spring lip in relation to the spring lid hinge is adjusted.

It is important to ensure that the small contact point of the lip is polished and lightly lubricated with bees wax. If the spring tension still appears too strong at this point, it can be lessened by narrow filing of the spring arm. (When the button is pressed, the spring lid must open gently and must not spring back!)

English bracket clock by John Ebsworth, ca. 1690

In this short documentation, I would like to describe a variant or option for replacing a lost drive chain for a fusee (chain/fusee system).

The images used here demonstrate to interested parties the highest level of quality. Even improper repairs with soft solder cannot conceal the quality of the original work. The compact design – for instance, this interior hour rack (lower image) – demonstrates the exceptional technical skill of the era. It was the beginning of a 100-year period of dominance for English clockmaking in the western world.

This bracket clock features a characteristic-sounding hour strike train and has a repeater mechanism that strikes the most recent quarter-hour on two bells.

The quarter snail of repetition on demand.

A spectacular technical marvel of its day.

To find a viable solution for the replacement of the drive chains, I opted for gut cords with specially designed hooks made of silver steel.

However, I later had to remove the upper nose as otherwise the hook would have got stuck when passing by the pallet bridge. I tied off the gut cord with a tightly wound silver wire. It’s robust and works flawlessly!